Hypergesture

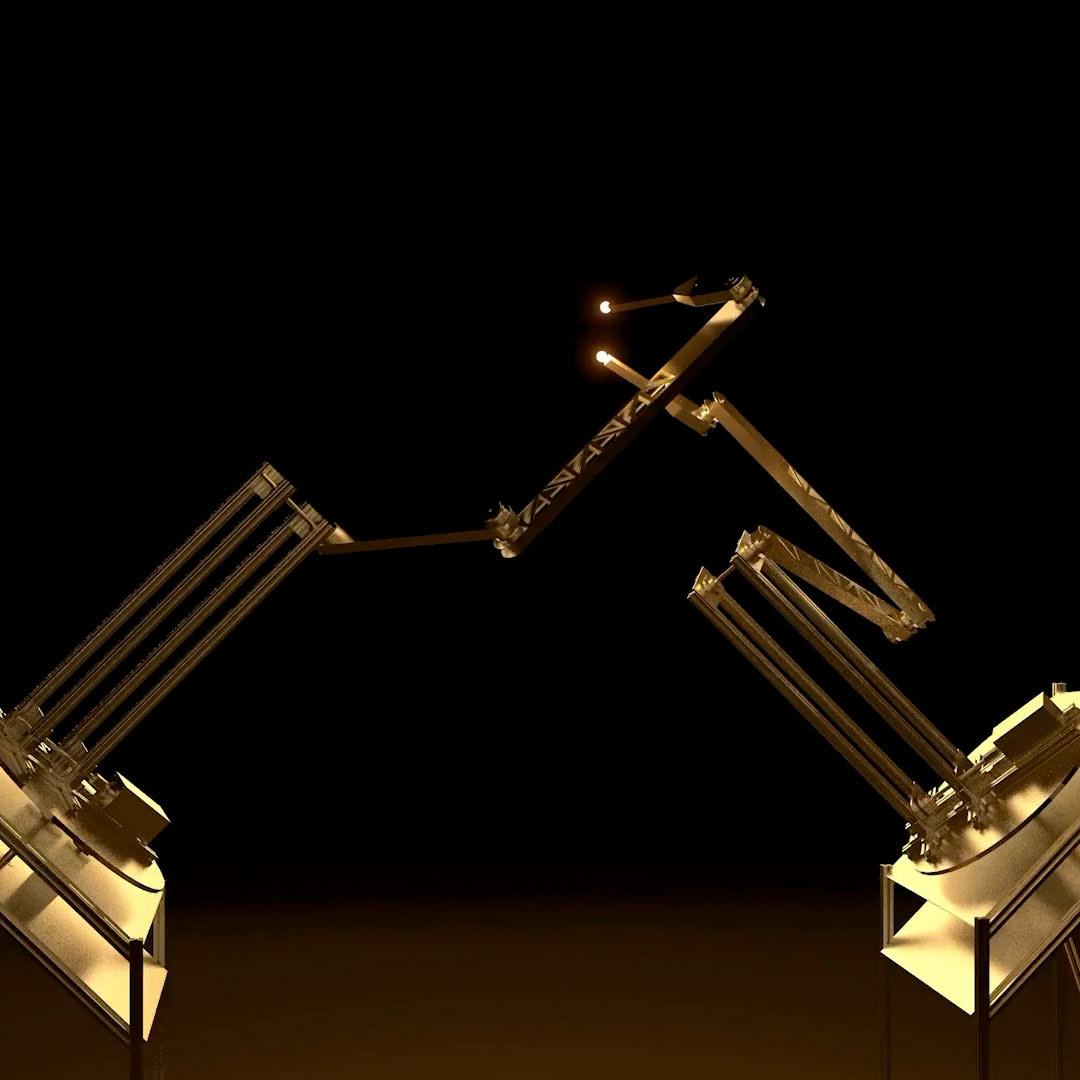

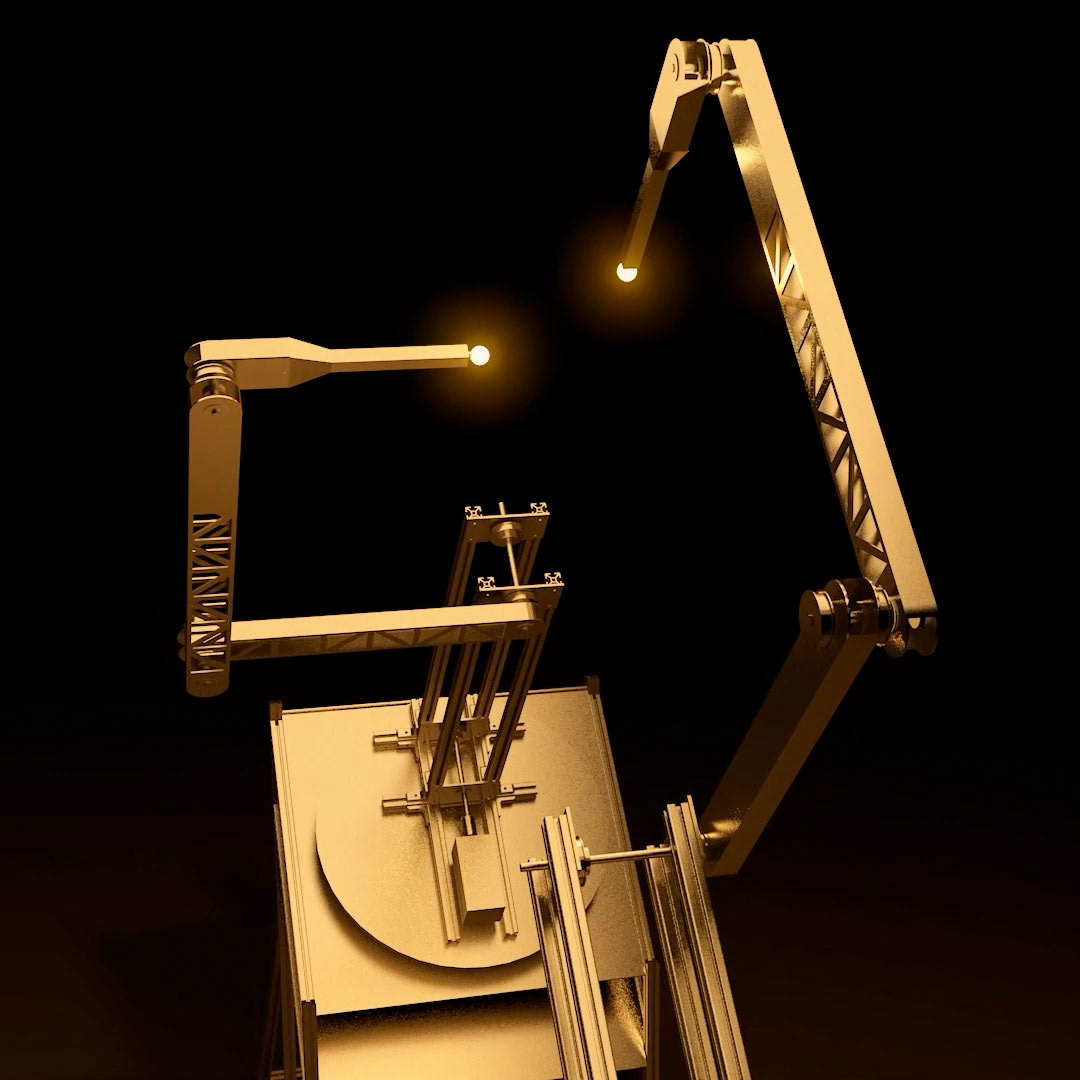

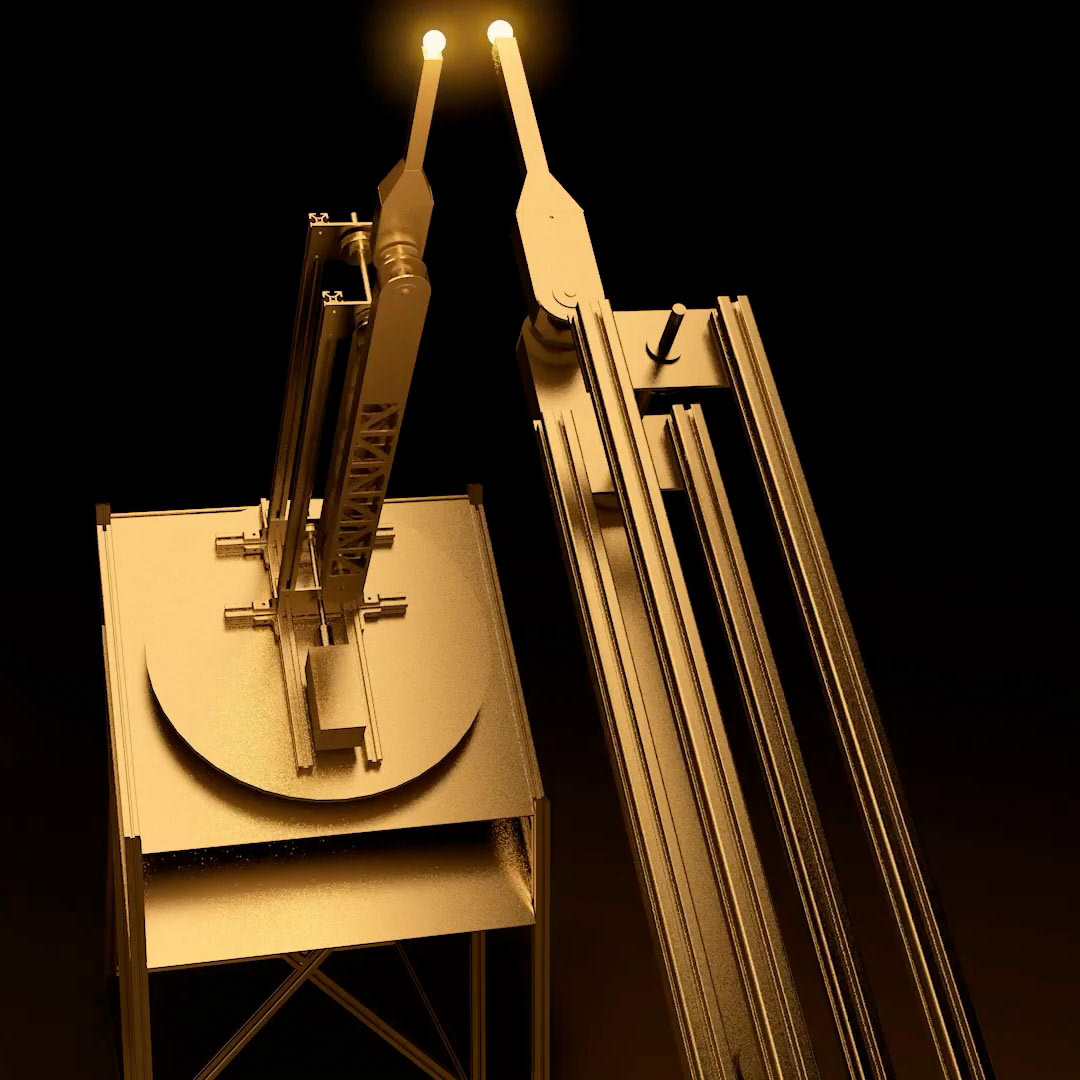

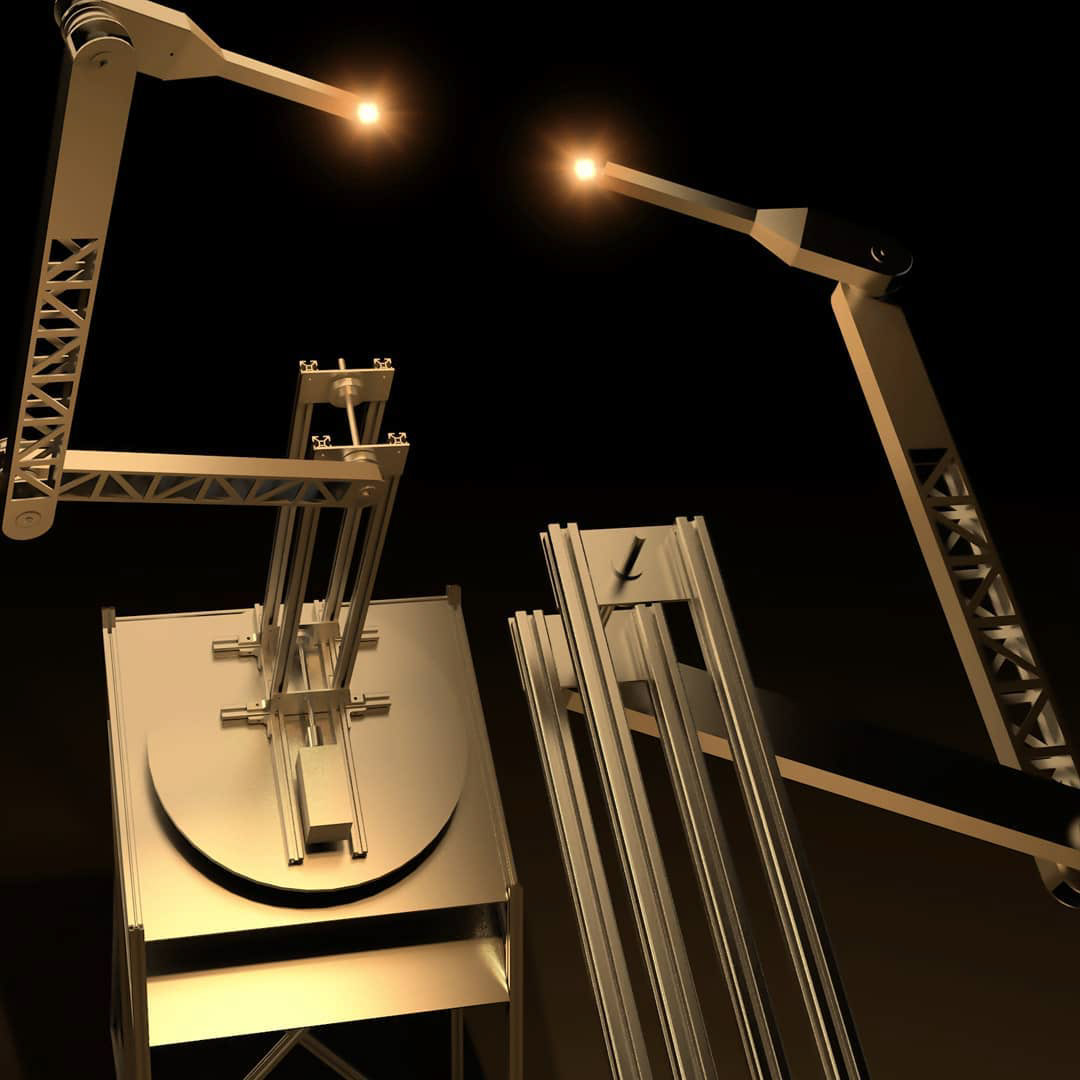

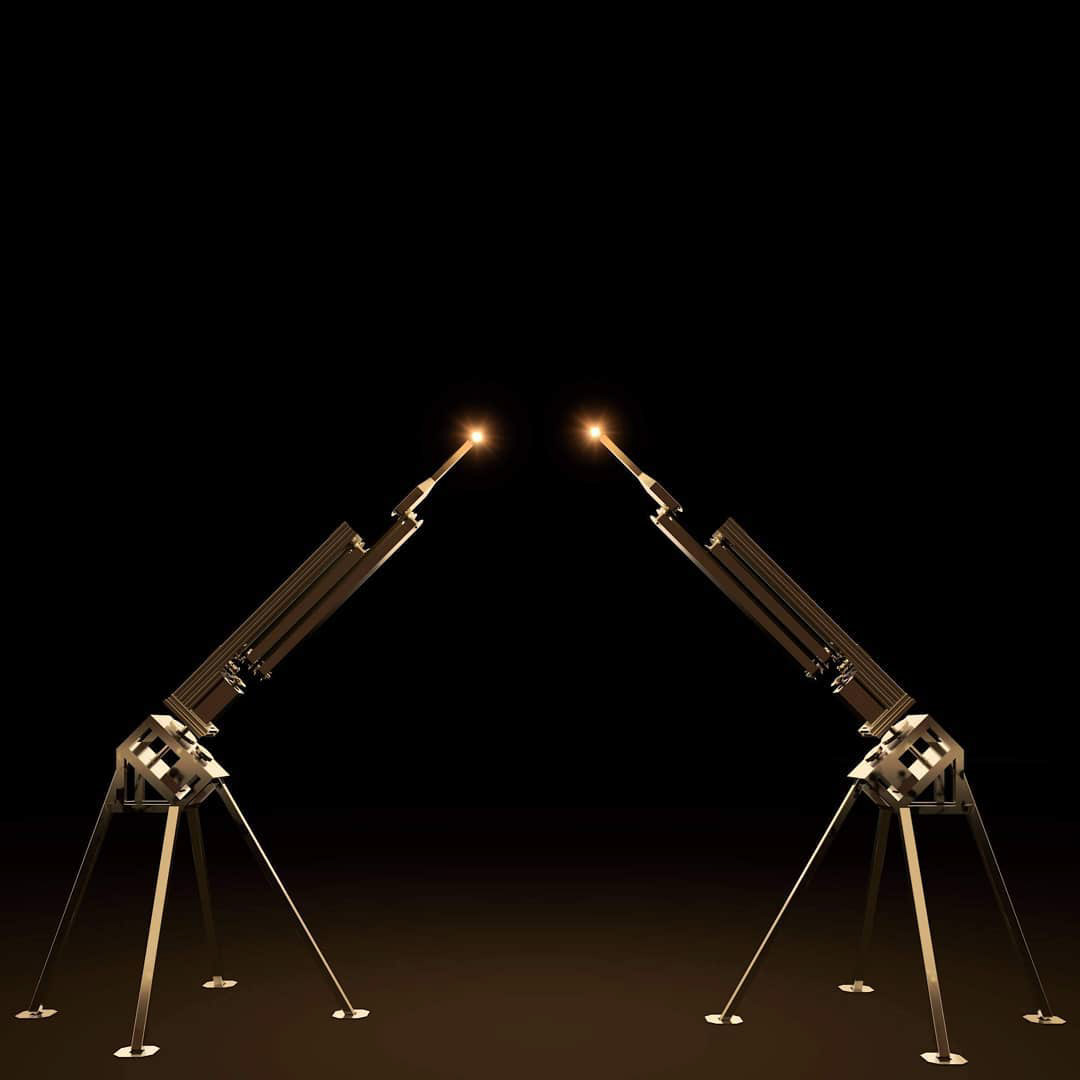

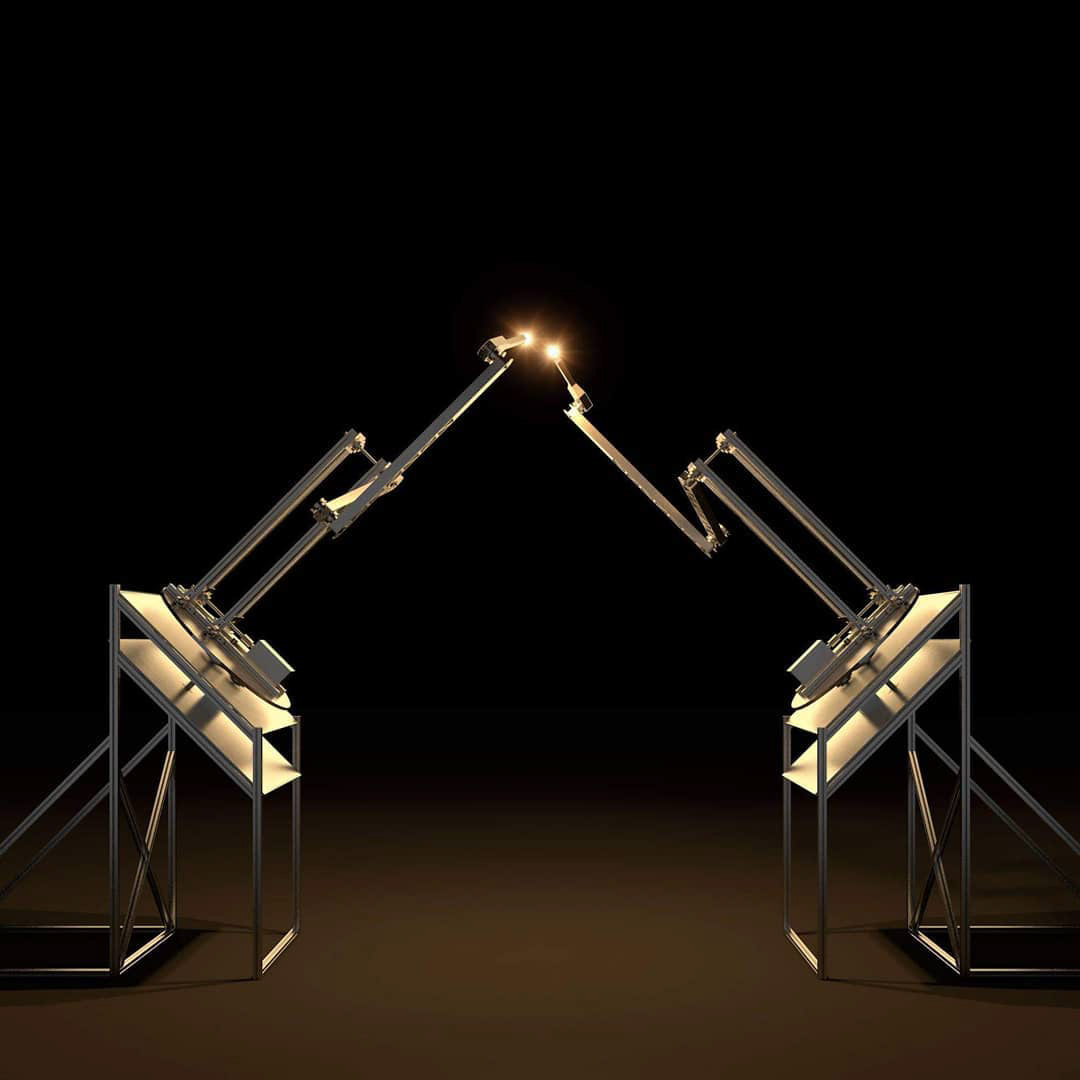

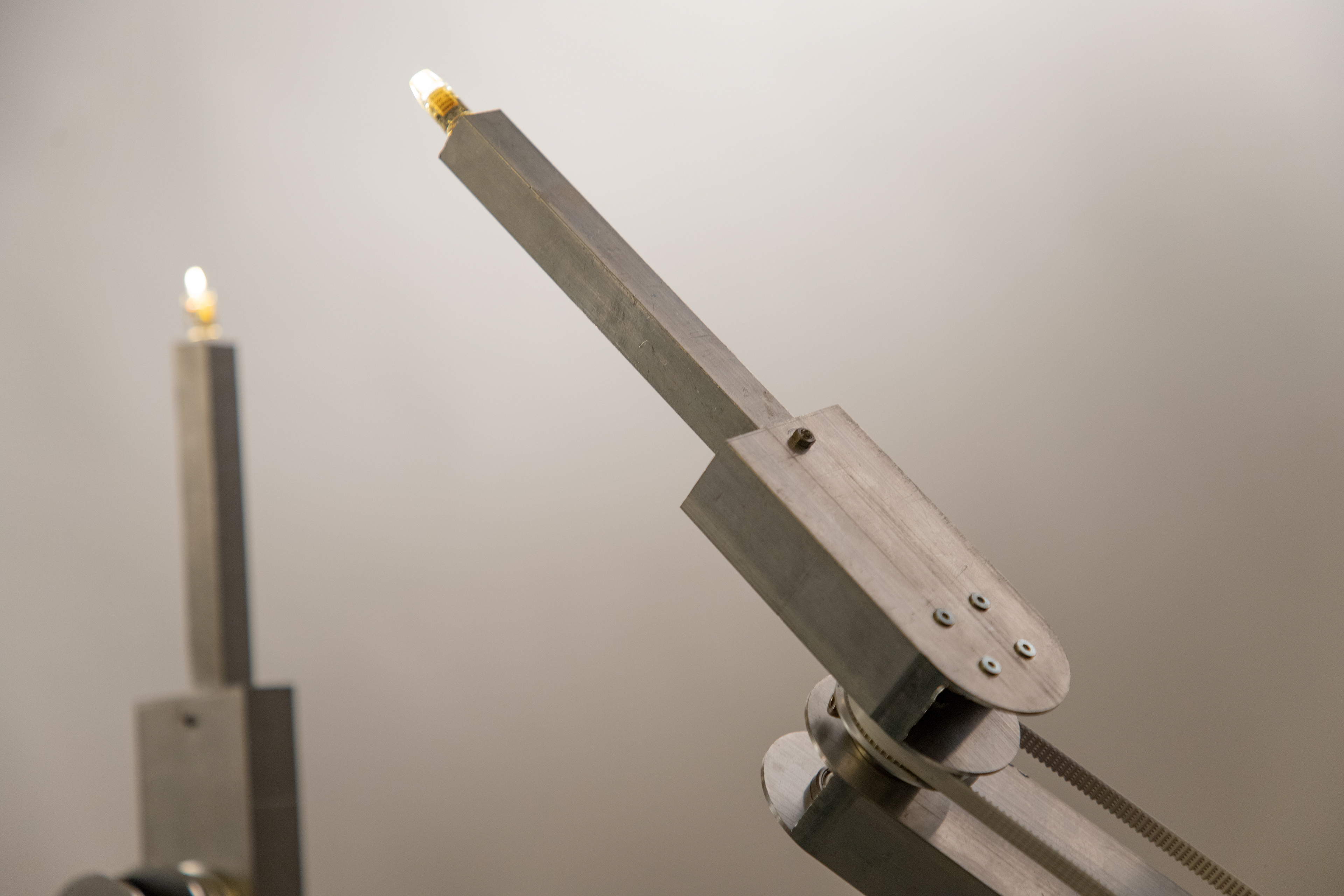

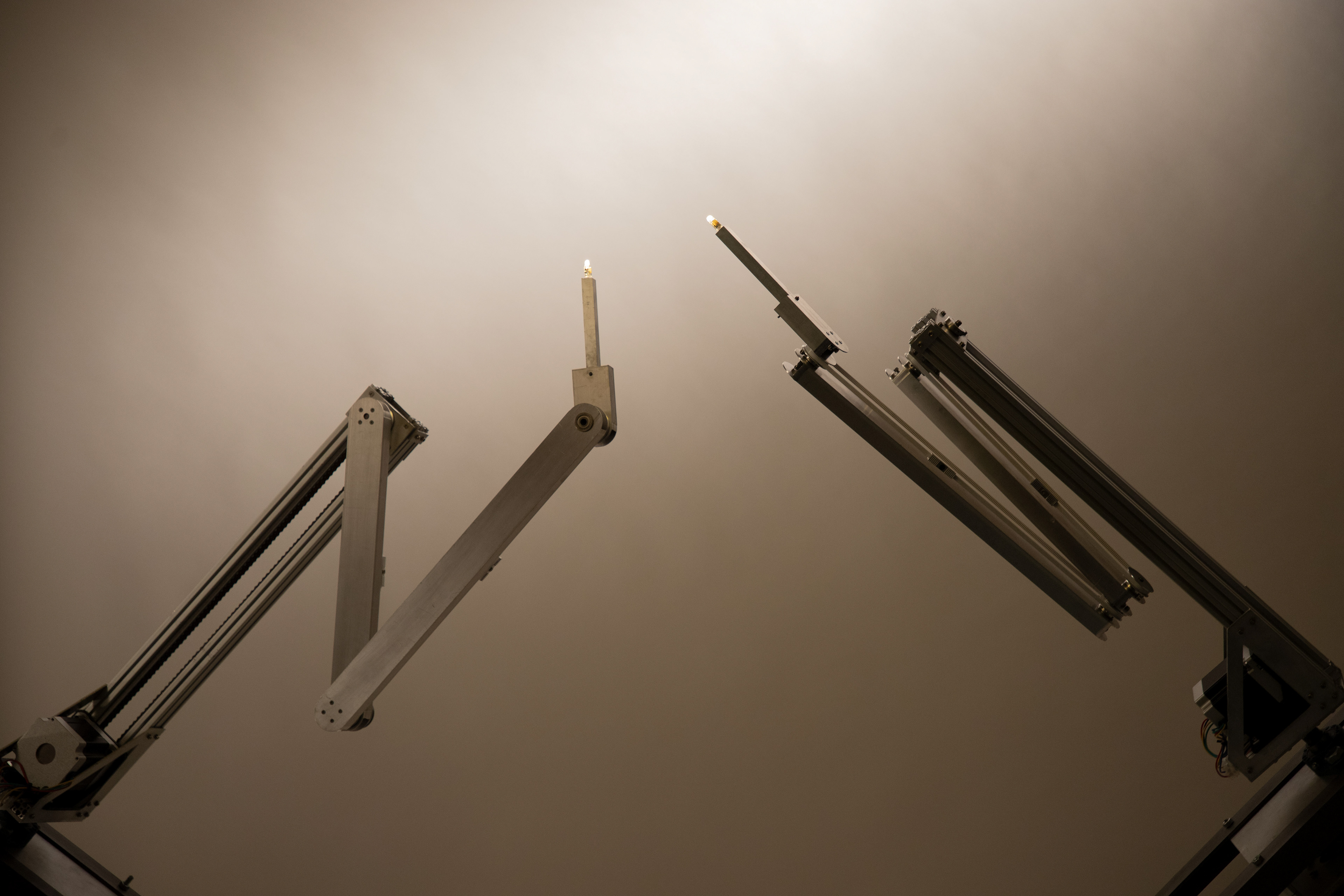

My final project on the Bartlett School of Architecture's MArch Design for Performance and Interaction course. A large-scale robotic installation consisting of two custom robot arms designed and manufactured by myself based on a design for a surgical robot which constrains the movement of the end effector to orbit around a single point in space. The two robots perform a dance duet together by performing movement sequences.

My final project on the Bartlett School of Architecture's MArch Design for Performance and Interaction course. A large-scale robotic installation consisting of two custom robot arms designed and manufactured by myself based on a design for a surgical robot which constrains the movement of the end effector to orbit around a single point in space. The two robots perform a dance duet together by performing movement sequences.

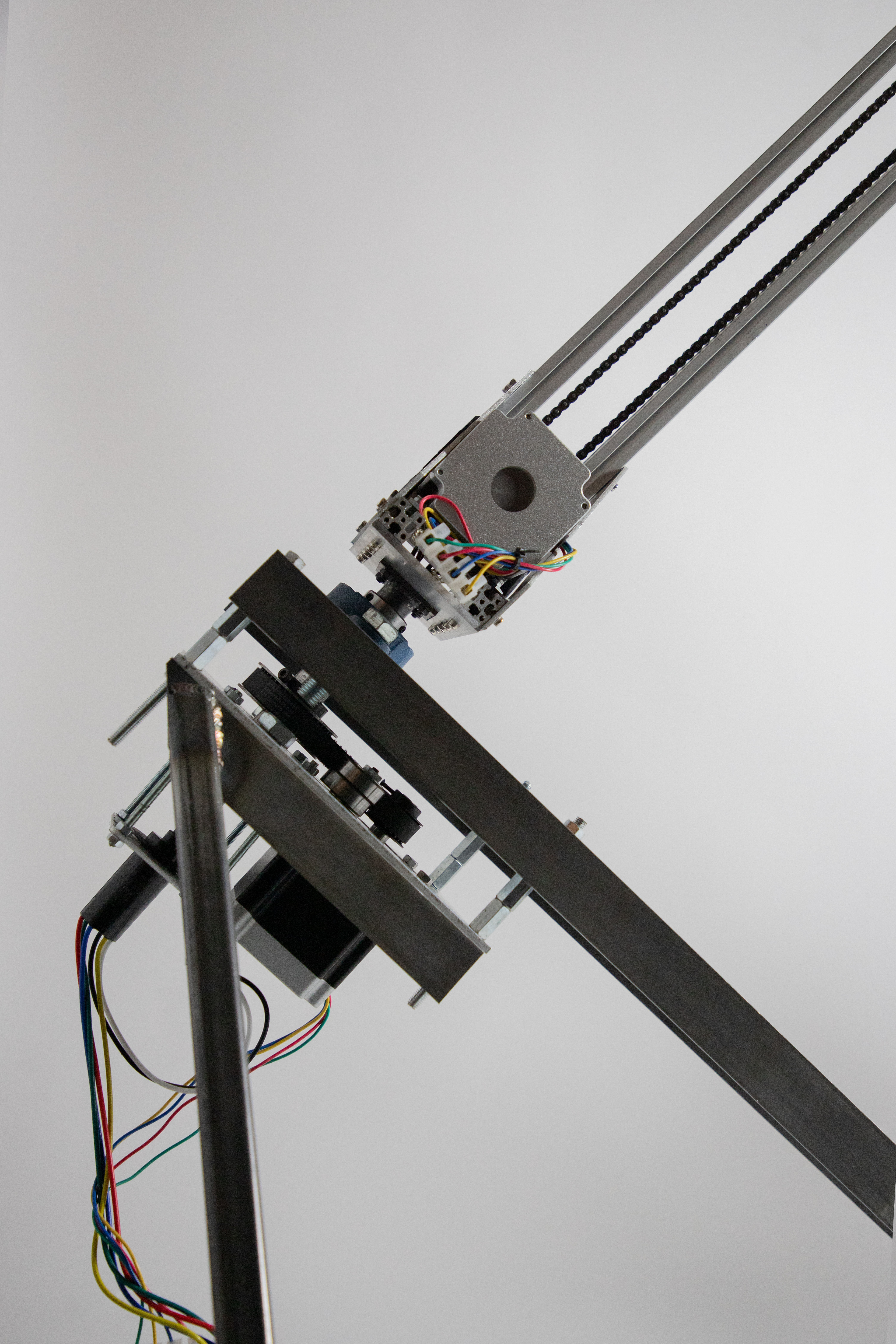

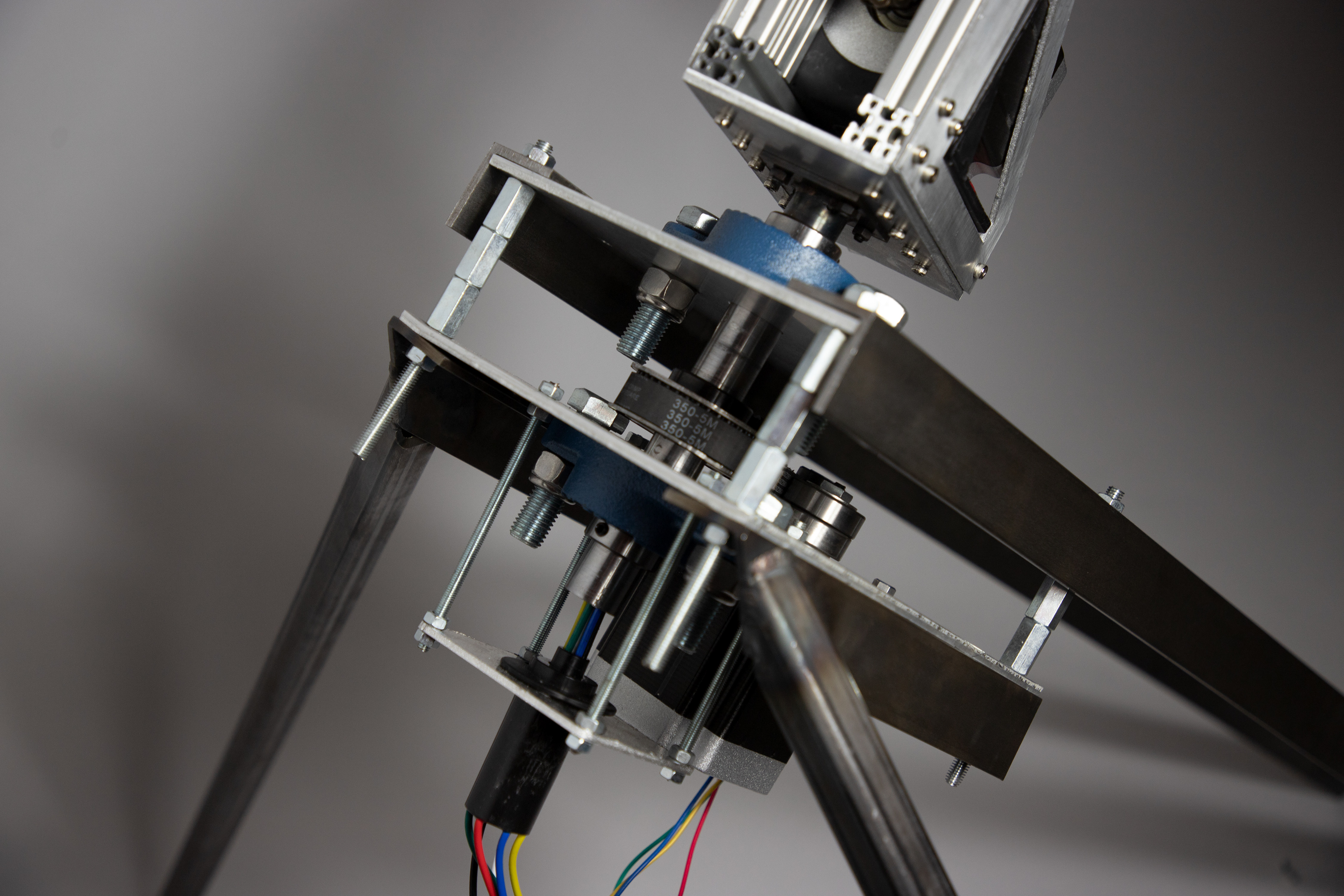

The movement is controlled by two stepper motors in the base which transmit rotation to the end effector through a system of belts, pulleys, chains and sprockets. The end effector is fitted with a warm white LED bulb to draw the attention of the viewer to the relationship between the two end effectors which share a spherical workspace. The spherical workspace echoes the Kinesphere, choreographer and dance theorist Rudolf Laban's conception of the range of motion of a dancer's body - a sphere formed by the reachable area from a standing position with limbs outstretched.

This project was featured in a book by Aesthetica Magazine and longlisted for the Aesthetica Art Prize.

Credits:

Robotics, concept and direction: John Lucy

Sound design and editing: Jakub Kubica

Filming: Aurelia Bergs, John Lucy

Dance: Laura Calcagno

Robotics, concept and direction: John Lucy

Sound design and editing: Jakub Kubica

Filming: Aurelia Bergs, John Lucy

Dance: Laura Calcagno

A set of behaviours was prototyped digitally using a realtime kinematic simulation in Three.JS driven by motion capture data from Alexander Whitley Dance Company's Digital Body project. A dancer responding to the movement of a solitary arm was also explored.

You can read about the theoretical basis of the project in my thesis titled:

The Recreation of Human Qualities of Movement in Semi-Anthropomorphic Robotic Systems.

The Recreation of Human Qualities of Movement in Semi-Anthropomorphic Robotic Systems.

Software:

Arduino, Three.JS, Fusion 360, Processing.

Fabrication:

Waterjet cutting, plasma cutting, welding, CNC machining, drilling, sawing.

Materials:

steel, aluminium, NEMA 34 stepper motors, stepper driver boards, belt and pulley transmissions, chain and sprocket transmissions.

Arduino, Three.JS, Fusion 360, Processing.

Fabrication:

Waterjet cutting, plasma cutting, welding, CNC machining, drilling, sawing.

Materials:

steel, aluminium, NEMA 34 stepper motors, stepper driver boards, belt and pulley transmissions, chain and sprocket transmissions.

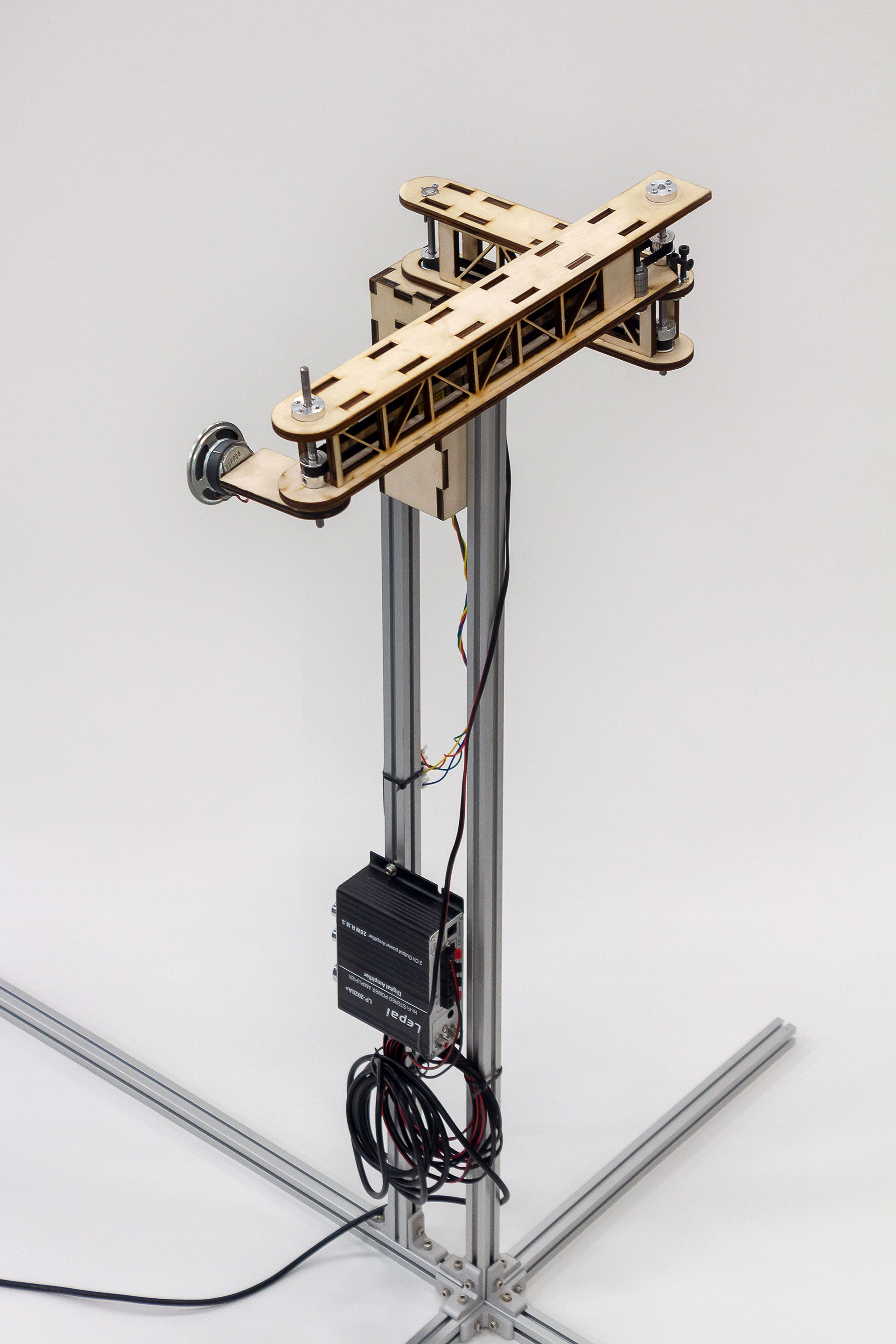

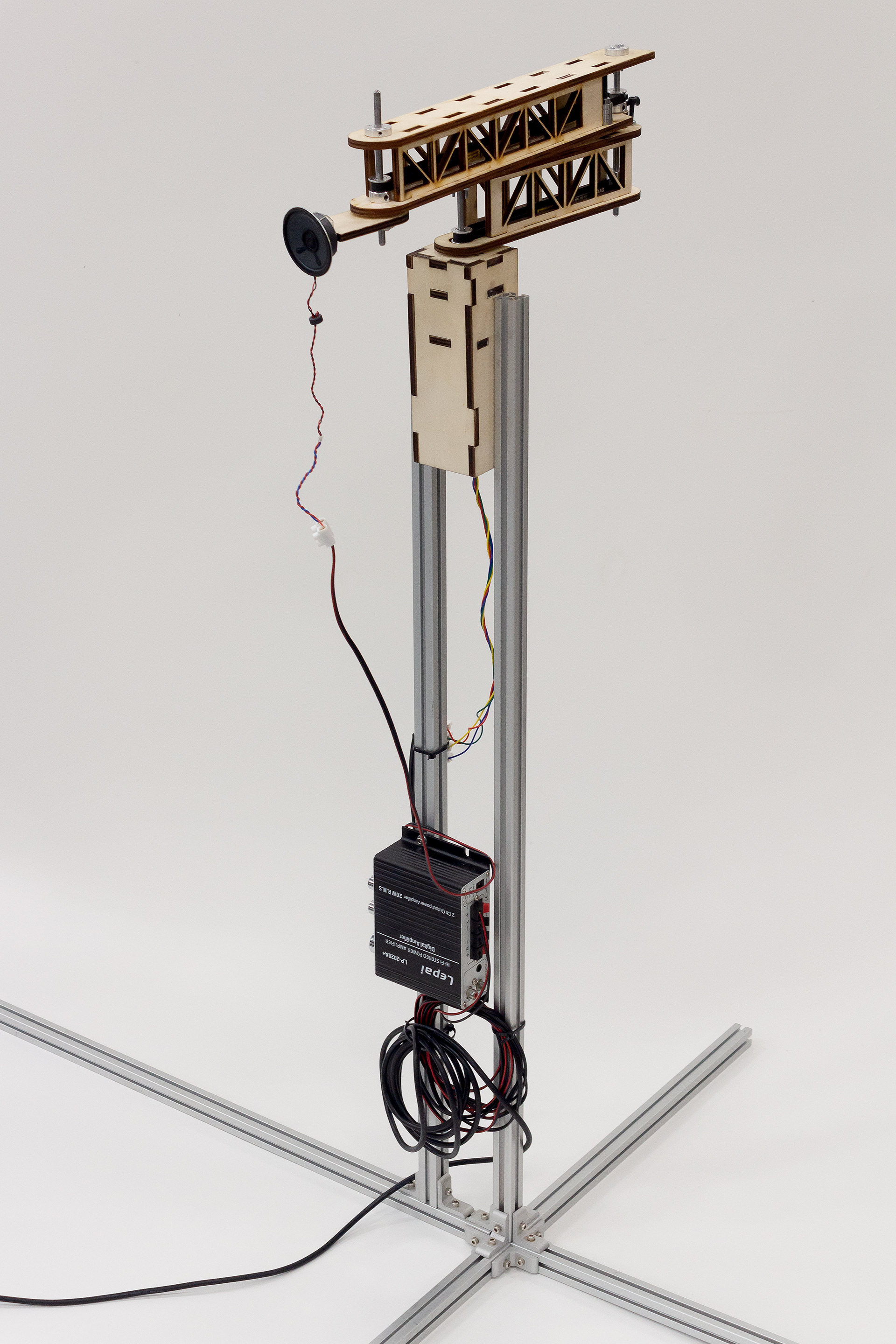

Initial Prototypes

The design originally comes from surgical robotics where the operating tool must be able to orbit around a single point in space accurately to approach a surgical site from different angles while minimising trauma to a patient's body. I was interested in constraining the robot to a perfect spherical motion and exploring the movement possibilities with a very small number of degrees of freedom - angles for longitude and latitude.

My first prototype was a parallelogram linkage that uses rigid lasercut links to constrain the end effector. My second prototype uses belt and pulleys inside of lasercut wooden enclosures to constrain the end effector to an arc movement driven by a stepper motor in the base.

The design originally comes from surgical robotics where the operating tool must be able to orbit around a single point in space accurately to approach a surgical site from different angles while minimising trauma to a patient's body. I was interested in constraining the robot to a perfect spherical motion and exploring the movement possibilities with a very small number of degrees of freedom - angles for longitude and latitude.

My first prototype was a parallelogram linkage that uses rigid lasercut links to constrain the end effector. My second prototype uses belt and pulleys inside of lasercut wooden enclosures to constrain the end effector to an arc movement driven by a stepper motor in the base.

Early renderings in Cinema4D